Heat Transfer Pipes/

Heat Exchangers

Nishiyama’s heat exchangers?featuring technology for improved heat transfer performance.

Nishiyama develops double-pipe heat exchangers with multi-petal heat transfer pipes whose thermal conductance drastically surpasses that of conventional double pipes. We also develop capillary insert heat transfer pipes leveraging multi-petal heat transfer pipes. Our newly-developed heat exchangers are used in various sectors to help increase efficiency and save energy.

Nishiyama’s heat exchangers

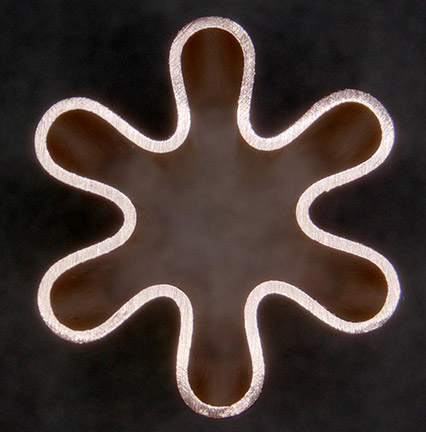

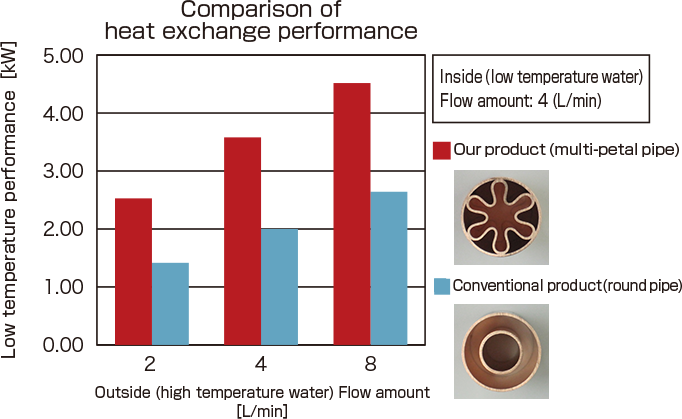

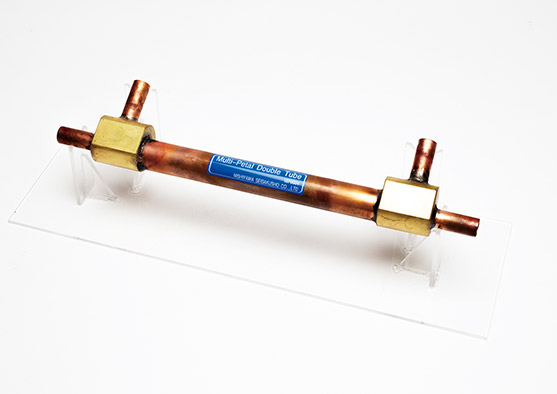

Double-pipe heat exchangers with multi-petal heat transfer pipes

Heat exchange efficiency increased by more than 2 times compared to conventional exchangers.

Nishiyama double pipes with multi-petal shaped inner pipes greatly increased the contact area between two liquids flowing on either side (heat transfer) without increasing the cross-section area to realize heat exchange efficiency that exceeds conventional products.

Three special characteristics

-

Compact and lightweight

Since our product has a large heat transfer surface compared to round pipes, it is possible to achieve a compact and lightweight design.

-

Various cross-section shapes

We can form various cross-section shapes using drawing methods. Small-diameter and ultra-thin pipes also possible.

-

Easy connection

We round out the edges of pipes to make connections easy.

high-efficiency heat exchangers We can form various cross-section shapes using drawing methods. Small-diameter and ultra-thin pipes also possible. We can also round out the edges of the multi-petal heat transfer pipes to make connections easy.

●Outer diameters of 10 to 35mm, thicknesses of 0.5 to 2.5mm and up to 12m in length are available (for specs outside this range, please inquire separately).

- Example product applications:

- Boiler reheating heat exchangers, high-voltage heat exchangers for CO2 refrigerants, S&T heat exchangers for compressors, heat exchangers for exhaust heat recovery, etc.

Nishiyama’s technologies

We developed heat transfer pipes with superior corrosion resistance.

Our multi-petal heat transfer pipes and high-efficiency heat exchangers can be produced with copper alloys, stainless steel and aluminum alloys. We can make pipes for any desired corrosion resistance, thermal resistance, light-weight or other specs (for sizes, please inquire separately).

Three advantages

-

High corrosion resistance

Uses stainless steel (SUS304, SUS316) and copper alloy (cupronickelC7060). Possesses superior corrosion resistance.

-

Durability at high temperatures

Stainless steel can be used at high temperatures which are not supported by copper.

-

Use with both salt water and fresh water

Copper alloy can be used in both salt water and fresh water. This usage was not possible with conventional products.

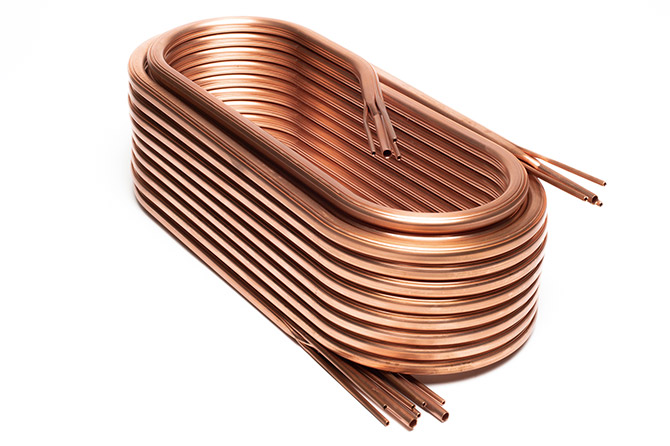

Capillary insert heat transfer pipes

Achieving flexible pipes with superior bendability.

Our superior bending process creates various shapes. Also compatible to substitute CFCs and CO2 refrigerants.

Two special characteristics

-

100% recyclable

We use the caulking method for soldering the capillary inserts. This eliminates the need for mixing metals in soldering such as brazing filler metals, thus achieving 100% recyclable materials and decreasing the environmental burden.

-

Support for flexible pipes

Our pipes feature superior bendability for formation into various shapes. This enables use as flexible pipes of heat exchangers.

Capillary insert heat transfer pipes We use the caulking method for soldering. 100% recycled materials can be used for solder without mixing metals such as brazing filler metals in order to keeping the environmental burden low.

- Example product applications:

- Water heat exchangers for home and commercial boilers