Work Process

Our special method for achieving high precision

Manufacturing Flow

-

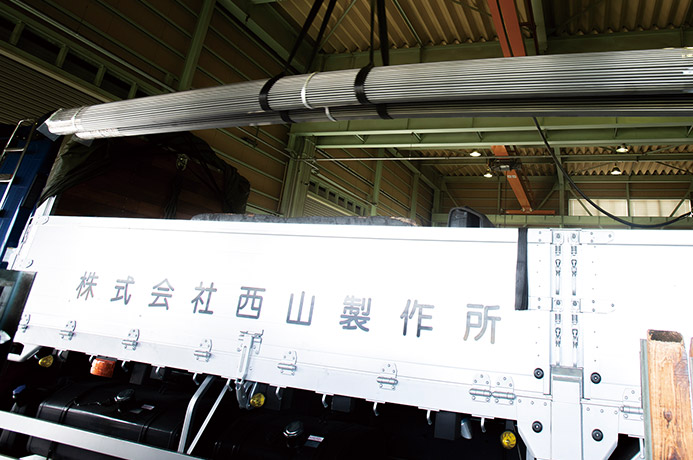

1.Materials

-

2.Cleaning

Remove oil and dirt. -

3.Heating

Pipes are annealed using non-oxidizing heat treatment furnaces without scales for an extremely beautiful surface finish that does not require pickling. -

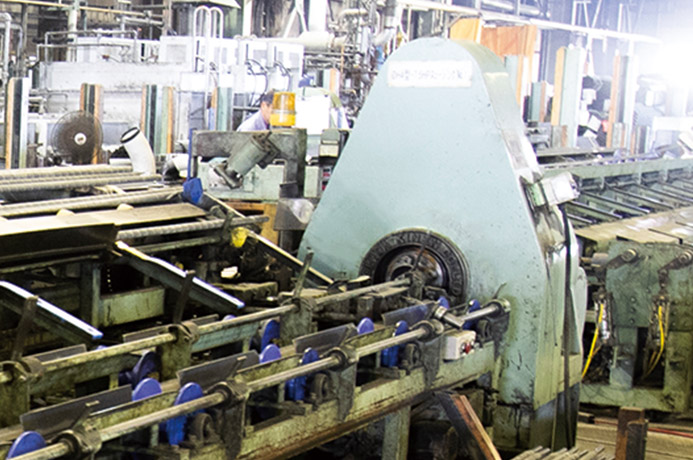

4.End processing

Pipe ends are squeezed and processed by dedicated machines -

5.Drawing

Cold draw processing provides a wide range of high-accuracy dimensions. -

6.Cutting

Beautiful cut edges made possible with special tools. -

7.Straightening

Multi-roll adjusting increases circular precision. -

8.Non-destructive inspection

Eddy current flaw detection equipment enables high-accuracy scratch discovery. -

9.Inspection

Product inspections are done carefully by each of our skilled inspectors who check every item visually. -

10.Packaging and shipping